Suppose about the last time you walked through a large plant floor machines humming, conveyor belts running, lights blazing across the installation. It’s a phenomenon of productivity, but there’s a hidden truth: factories consume massive quantities of energy, and much of it is wasted. Enter the Internet of Things (IoT). With smart apps and connected devices, manufacturers are slashing energy bills, improving efficiency, and moving toward sustainable growth.

What’s Smart Manufacturing?

Smart manufacturing is the evolution of traditional production into a fully digital and connected ecosystem. It’s where IoT, AI, cloud computing, robotics, and data analytics meet to create highly adaptive and energy-efficient factories. Instead of operating blindly, smart factories leverage data to make decisions in real time.

The Energy Challenge in Manufacturing

Energy costs can eat up nearly 30–50% of a manufacturer’s operating expenses. From heating massive installations to powering heavy machinery, inefficiencies pile up quickly. Older equipment often runs at peak power even when demand is low. Without smart insights, companies end up paying for energy they don’t actually need.

How IoT Apps Transform Energy Management

IoT apps act like the nervous system of a factory. Connected sensors and devices feed data into centralized dashboards. This enables:

- Real-time monitoring of energy consumption per machine.

- Automated control systems that adjust usage instantly.

- Predictive analytics to forecast demand and prevent waste.

Instead of reacting to problems, manufacturers can anticipate them.

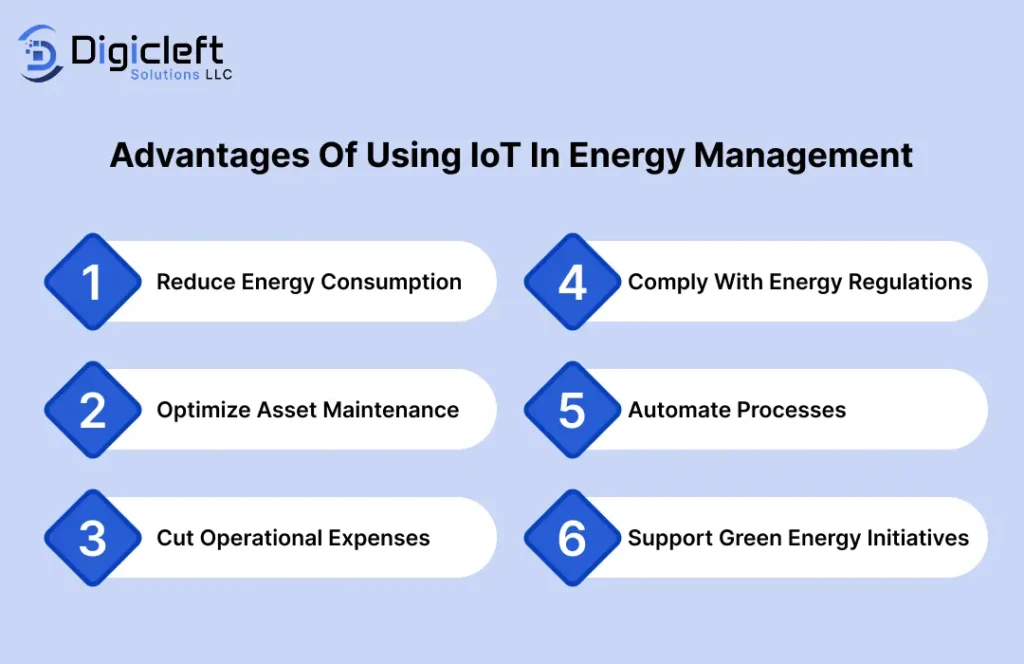

Key Benefits of IoT in Reducing Energy Costs

- Improved Equipment Utilization – Machines run only when necessary.

- Automated Energy Optimization – Smart apps dim lights, regulate HVAC, or shut down idle systems.

- Waste Reduction – Less energy wasted equals direct cost savings.

Real-Time Data Monitoring and Its Impact

Imagine being able to see exactly how much power each machine uses at any moment. IoT makes this possible. Operators receive live feedback, allowing them to quickly spot anomalies. For example, if a motor is drawing more power than usual, maintenance can step in before it fails.

Predictive Maintenance and Energy Savings

Traditional maintenance often waits for equipment to fail, but IoT flips the script. By analyzing sensor data, factories can predict when a machine will need servicing. This reduces downtime and eliminates excessive energy draw from failing systems.

Smart Grids and IoT Integration

IoT-enabled factories can sync with smart grids to optimize energy use. During peak hours, machines can shift workloads to off-peak times. Some facilities even integrate renewable energy, like solar or wind, directly into production schedules reducing reliance on expensive grid power.

Case Studies: IoT in Action

- Automotive Industry – Auto manufacturers use apps to regulate robotic assembly lines, cutting electricity costs by up to 20%.

- Food & Beverage – Refrigeration units are monitored in real time to prevent energy waste while ensuring product safety.

- Electronics Manufacturing – Smart HVAC systems adapt airflow and cooling, slashing climate control costs.

The Role of AI in IoT-Powered Energy Efficiency

IoT gathers data, but AI makes sense of it. Machine learning algorithms identify patterns, optimize scheduling, and make autonomous adjustments. It’s like giving the factory a brain that learns how to save energy with each cycle.

Cost Savings Beyond Energy Bills

When machines run efficiently, they last longer. Predictive insights also reduce expensive breakdowns. Beyond lowering electricity bills apps deliver savings in maintenance, labor, and equipment investment.

Challenges in IoT Implementation

- Cybersecurity risks – More connectivity means more entry points for hackers.

- High upfront costs – Installing IoT infrastructure requires investment.

- Skill gaps – Workers must adapt to managing digital ecosystems.

Still, the long-term ROI outweighs the hurdles.

Digicleft Solution: Powering Energy Efficiency

When it comes to practical deployment, the Digicleft solution stands out. By integrating IoT apps designed specifically for smart manufacturing, Digicleft enables factories to cut energy waste, monitor systems in real time, and optimize processes seamlessly. With tailored dashboards and predictive tools, this solution helps manufacturers unlock savings while future-proofing their operations.

Future of IoT in Smart Manufacturing

The next chapter of smart factories looks even more exciting:

- 5G connectivity for instant decision-making.

- Edge computing to process data closer to the machines.

- AI-driven autonomous operations that make factories self-sufficient.

In short, the future belongs to energy-smart factories powered by IoT.

Conclusion

IoT apps aren’t just about connectivity they’re about making factories lean, green, and cost-effective. From predictive maintenance to smart grids, IoT is reshaping how manufacturers consume and conserve energy. And with innovators like Digicleft leading the way, the shift toward smarter, sustainable manufacturing is no longer optional it’s essential.

FAQs

- What industries benefit most from IoT energy solutions?

Automotive, food processing, textiles, and electronics are among the top beneficiaries. - How does IoT improve sustainability?

By minimizing energy waste, reducing emissions, and enabling integration with renewable sources. - Is IoT suitable for small manufacturers?

Yes, modular IoT apps allow even small businesses to apply cost-saving measures. - What role does AI play in energy efficiency?

AI analyzes IoT data to optimize machine usage, predict failures, and automate energy controls. - How can companies get started with IoT apps?

They can begin with pilot systems using solutions like Digicleft, then scale gradually.