Let’s be honest manufacturing has come a long way from the days of homemade assembly lines and guesswork. Today, data is the lifeblood of the industry, and artificial intelligence (AI) is its beating heart. Together, they’re rewriting the rules of production, quality, and efficiency.

Manufacturers worldwide are embracing data-powered AI systems that don’t just optimize processes they learn, predict, and innovate. And with players like Digicleft Solution driving digital transformation, the era of smart manufacturing has truly begun.

The Evolution of Manufacturing Intelligence

From Automation to Autonomy

Early automation followed strict rules. Modern AI systems, however, adapt. They analyze data, learn from experience, and make real-time decisions without human input. This leap from rule-based logic to adaptive intelligence marks the birth of the autonomous factory.

Data-Driven Decision-Making

Manufacturers no longer rely solely on intuition. With massive data flows from sensors, IoT devices, and machines, companies can anticipate issues before they occur, boosting productivity and quality at once.

The Role of Data in Modern Manufacturing

From Data to Insight

Every machine, conveyor belt, and sensor generates data — tons of it. The magic happens when AI turns that raw stream into actionable intelligence. It’s like refining crude oil into high-octane energy — powering smarter operations.

Adaptive Manufacturing

Data empowers factories to be flexible. If demand changes or a supply chain hiccup arises, adaptive AI systems can adjust production in real time, minimizing waste and maintaining efficiency.

AI and Data: The New Power Duo

Machine Learning Applications

Machine learning (ML) allows systems to detect patterns invisible to the human eye. In manufacturing, ML identifies anomalies, optimizes scheduling, and predicts future outcomes with remarkable precision.

Deep Learning for Quality Assurance

Deep learning models excel at visual inspection. Cameras powered by neural networks can detect even the tiniest defects on production lines faster and more reliably than human inspectors.

Emerging AI Trends Reshaping the Sector

- Predictive Maintenance: AI predicts when a machine will fail before it actually does enabling proactive maintenance and reducing downtime.

- Generative Design: AI-powered software creates product designs optimized for strength, weight, and cost — beyond human imagination.

- Supply Chain Optimization: Data analytics predicts demand fluctuations, streamlines logistics, and reduces delays — keeping the global supply network nimble.

- Robotics and Cobots: Collaborative robots (cobots) work with humans to boost safety and productivity.

- Energy Efficiency: AI helps monitor power use, identify inefficiencies, and reduce energy costs while supporting sustainability goals.

Predictive Maintenance: The Fortune Teller of Machines

Downtime is a manufacturer’s worst nightmare. Predictive maintenance turns that fear into foresight. By analyzing sensor data, AI predicts when equipment parts are likely to wear out allowing technicians to act just in time. Companies like Siemens and GE have adopted this approach, cutting unplanned downtime by up to 50%.

Generative Design: When Machines Become Creators

Generative design tools use AI to explore countless design possibilities based on constraints like materials, budget, and performance needs. The result? Products that are lighter, stronger, and more cost-effective. In essence, machines are becoming co-designers of the future.

Smart Factories and the IIoT

The Industrial Internet of Things (IIoT) is the nervous system of modern manufacturing. Sensors connect every part of the process, sending data streams to centralized AI systems that interpret and act upon them.

Edge Computing: Speed at the Source

Edge computing processes data close to where it’s generated, reducing latency and enabling instant decision-making resulting in faster responses and tighter control.

AI in Supply Chain Optimization

AI thrives in complexity and the global supply chain is no exception. From predicting raw material shortages to optimizing routes and warehouse operations, AI makes supply chains resilient. Manufacturers using AI-based forecasting report up to 20% lower inventory costs and faster delivery cycles.

Energy Management and Sustainability

AI isn’t just about profits it’s about planet-positive progress. Intelligent systems monitor energy use, optimize resources, and reduce emissions. Imagine a plant that powers down idle machines during off-peak hours that’s AI at work for sustainability.

The Human-AI Collaboration

AI isn’t here to steal jobs it’s here to elevate them. Humans bring creativity and context; AI brings speed and precision. By automating repetitive tasks, workers can focus on problem-solving, innovation, and strategy.

Forward-thinking companies like Digicleft Solution are helping bridge the gap by empowering teams with the tools and training to thrive in AI-driven environments.

Cybersecurity in AI-Driven Manufacturing

As factories become more connected, data security becomes critical. Cyberattacks on industrial systems can cripple operations. Manufacturers are now investing in AI-driven cybersecurity systems that detect and neutralize threats in real time before any damage occurs.

The Role of Digicleft Solution in Smart Manufacturing

Digicleft Solution stands at the forefront of this digital shift. By combining data analytics, AI integration, and custom automation, it helps manufacturers transition from traditional operations to intelligent ecosystems. Their focus on data strategy, predictive insights, and process optimization ensures that every plant they touch becomes smarter, leaner, and more resilient.

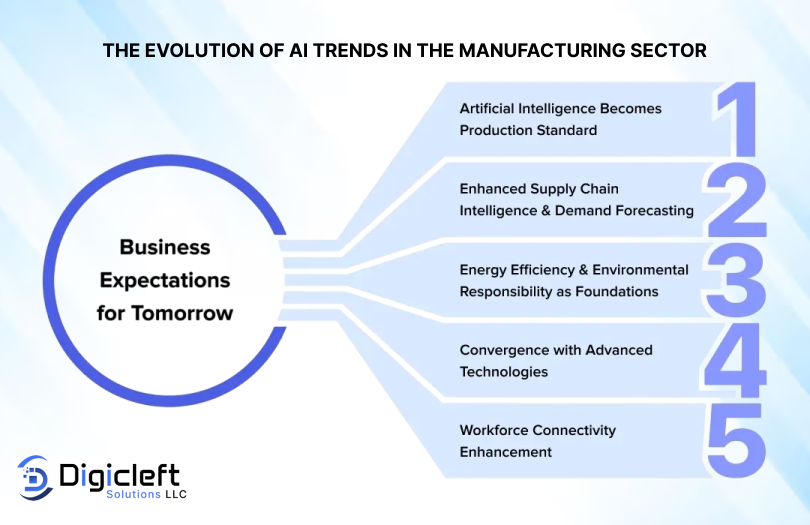

Future Outlook: Where AI and Data Are Headed

The future points to fully autonomous factories systems managing everything from production to logistics with minimal human input. Technologies like digital twins virtual replicas of real-world systems will allow manufacturers to test and optimize before implementing changes physically. The result? Near-zero errors and unmatched agility.

Conclusion: The Data-Driven Dawn of Manufacturing

Data and AI are not just tools they’re the foundation of modern manufacturing. They empower industries to predict, adapt, and grow in ways once unimaginable. With innovators like Digicleft Solution leading the charge, the manufacturing world isn’t just getting smarter it’s becoming self-aware. The future belongs to those who embrace the power of data today.

FAQs

1. What’s the biggest impact of AI on manufacturing? AI boosts efficiency, reduces downtime, and enhances decision-making through predictive analytics.

2. How does data improve manufacturing quality? Data helps identify trends and defects early, ensuring consistent and high-quality production.

3. What is predictive maintenance in manufacturing? It uses AI to forecast equipment failures, allowing timely maintenance and avoiding costly shutdowns.

4. Why is Digicleft Solution important in smart manufacturing? Because it provides data-driven AI solutions that accelerate digital transformation and innovation in the sector.

5. What’s next for AI in manufacturing? Expect fully autonomous systems, AI-driven design, and digital twins redefining industrial intelligence.